|

| |

|

Summary

Silicon Carbide (SiC) is one of traditional material for making kiln furniture. Thermal rupture strength of SiC is much higher than the cordierite-mullite which means the loading capacity of this material is much higher than cordierite material, this can reduce the weight of kiln furniture for same loading capacity and increase the loading efficiency inside kilns. Meanwhile SiC has high thermal conductivity which brings very high heat efficiency toward to products. The high refractoriness of SiC makes it workable up to 1,500℃.

Modern advanced SiC based materials, i.e. SiSiC, NSiC & RSiC, bring even higher loading capacity & other property improvement, this reduces the weight of kiln furniture self furtherly.

Products

The SiC can be used in lots of applications especially for advanced SiC based materials, we are listing the kiln furniture purpose only.

| 1.Conventional SiC |

|

|

|

|

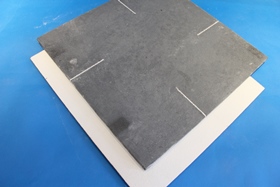

Batt / Shelf / Slab |

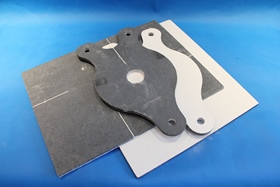

Support |

Setter |

| 2.Advanced Silicon Carbide Based Materials |

|

|

|

|

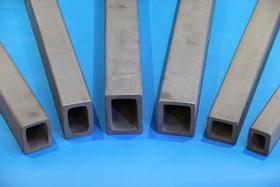

Beams |

Burner Tube |

Cooling Tube / Rollers |

|

|

|

|

|

Batt / Shelf |

Support |

|

We listed only one or two typical products and cut the products to suit photograph here, for more information about sizes and shapes of our silicon carbide kiln furniture, please contact with our engineers. |

|

|

|

Sanitary wares |

Both traditional SiC and advanced SiC (especially SiSiC) are used widely for firing sanitary wares.

Typical Product:SiSiC Beams, Kiln Car Plate, Lavatory setters, Support (Post) & Firing Setters

Suited Kiln: Tunnel Kiln, Shuttle Kiln & Roller Kiln |

|

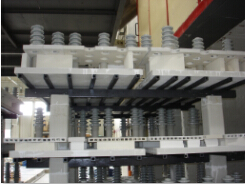

Porcelain Insulator |

Traditional SiC is used to fire insulator with heavy support blocks & setting batts, recently the advanced SiC kiln furniture has been introduced to set up the low thermal mass kiln car for insulator as well.

Typical Product:SiSiC Beams, RSiC Beams, Plate (Batts), Support (Post) & Holding Setter

Suited Kiln: Tunnel Kiln, Shuttle Kiln

|

|

Tableware |

Table wares firing is one of the common application for SiC kiln furniture especially for porcelain while the firing temperature either was higher than 1,300℃ or was with reduction atmosphere.

Typical Product:Shelf (Batts), TFS setter & Supports

Suited Kiln: Tunnel Kiln, Shuttle Kiln, Roller Kiln, Rotary Kiln |

|

Technical Ceramics |

In the firing process of technical ceramics, i.e. honeycomb ceramics & ceramics brakes, SiC is good option as either basic supporting material or Ultra-spacious structure.

Typical Product:SiSiC Beams, Plate (Batts), Support (Post), Saggars

Suited Kiln: Tunnel Kiln, Shuttle Kiln | |

|

|

|

|

|