Refractories in kiln cars can be divided as car base & top furniture. Both of them needs to be heated up and cool down during firing process, ECO kiln car system aims to reduce the weight of kiln cars' refractories by selecting modern materials and optimizing the structure, more heat will be used to heat up the fired products, improve the air circulation inside kilns and shorten the firing cycle once firing curve allowed.

|

|

|

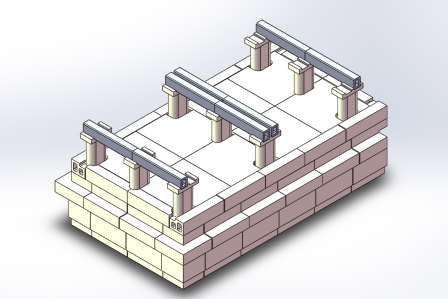

Conventional Kiln Car with Bricks & Supports |

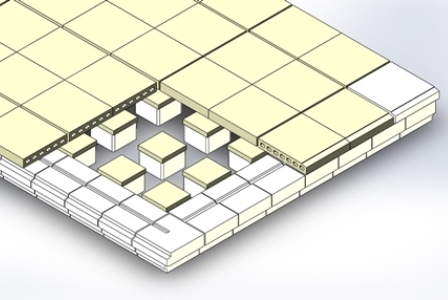

ECO-Kiln Car |

|

|

|

Conventional Car Base with all Heavy Bricks |

ECO-Kiln Car Solution |

| Except fuel waste, the duration and maintenance are another two problems as well normally for the conventional kiln car surrounding area. For brick cars, the mortar will get loose after running due to thermal expansion different between bricks and mortar or discontinuous kiln car pusher. For fibers cars, the mechanical hitting and fiber crystallization are two main reasons to cause seal's broken. The re-lining needs to be done around the whole broken area instead of only the broken piece. |

|

|

|

Mortar Failure of Refractory Brick Cars |

Run off Seals of Pure Ceramic Fiber Cars |

| |

|

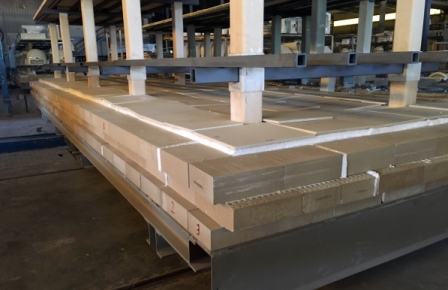

| Not only loading capacity & insulation performance need to be considered while employment the ECO kiln car system, other factors, i.e., position of burners, system stability, capital cost, service life & maintenance friendship, need to be considered as well, BRAVE STONE can provide you the tailor made engineering design, performance & cost analysis, materials and installation service. It is available for both new kiln project and converting traditional kiln cars to ECO kiln car system. |

|

|

|

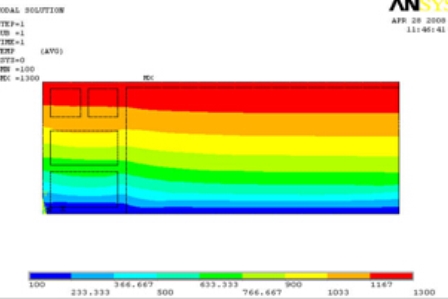

3D Engineering Design |

Thermal Analysis |

|

|

|

Cordierite Blocks with Ceramics Fibers |

Mortar Free Bricks with Ceramics Fibers | |