Instead of traditional refractory brick linings & ceramic fiber module linings, BRAVE STONE prefers to recommend the following ECO kiln lining solutions for our customers, you will see why we did not recommend traditional kiln linings and how to convert the traditional kiln linings to ECO-kiln linings later on in this page.

|

|

|

ECO-Kiln Lining A, ceramics plate + ceramic fiber |

|

|

|

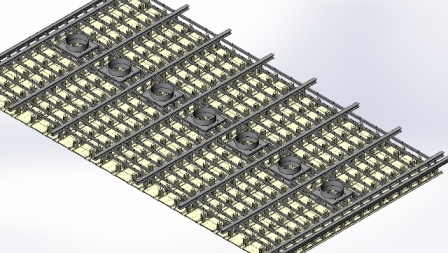

ECO-Kiln Lining B, supper size ceramic fiber module |

|

|

|

ECO-Kiln Lining C, refractory brick + ceramic fiber |

| |

|

|

Traditional Refractory Brick Linings |

|

Waste energy - Heavy with high thermal capacity for intermittent kilns. |

| Heat leakage - Bricks dropping due to rusted hanger, brick broken & mortar failure |

| Wasted steels - Heavy linings needs extra steel works to hold kiln linings. |

| The cost of this system is lower normally than fiber linings especially for high temperature application, the high refractoriness bricks are available. Shape of roof can be arch instead of flat. |

|

| |

|

|

Traditional Ceramics Modules |

| Heat leakage - Shrinkage of fibers enlarge the gaps between modules |

| Kiln Contamination - Crystallized ceramic fibers & melted iron from the rusted steel structure may fall inside the kiln into fired products. |

| High cost - especially while the temperature was higher than 1,300≧. |

|

Energy consumption is relative lower for this system, but with soft surface, it is easy to broken by mechanical attack & chemical steam erosion. Once broken area & open gaps appeared, it is not easy to repair, it will be broken continuously. |

| |

|

To change kiln lining from traditional ways to ECO solutions is a system job, engineers from BRAVE STONE can provide you the turn-key service from inspection of existing system, to engineering design, material supply and then site installation. Updraft flues with sizes over 1m x 1m is not a problem as well for us, we have tailor made solution for it.

|

|

|

Engineering Design |

Rusted Steel Frame by Leaked Hot Air | For more information or question, please contact with our engineers. |